DI

Combustion Chamber Design

Large

Large slow running DI engines (under 1500 rpm) have 'open

chambers' where the piston has a very shallow dish shaped

with a bump in the middle. Air movement is minimal and the

multi hole injectors (often 8-12 hole) are set to inject a

fine mist into the dish. Due to the size of the combustion

chamber sufficient air is present to supply the fuel with

oxygen and the fuel combusts before it contacts surfaces of

the combustion chamber.

Small

With smaller higher speed engines it is not possible to produce

injectors with the multiple very small holes that would be

necessary to provide sufficient fuel distribution. The number

of holes is therefore reduced (3-5 hole). To achieve better

fuel/air mixing air turbulence is induced within the combustion

chamber.

Incoming air is set into rotation by the inlet valve being

positioned to one side of the cylinder head. The air rotates

around and down the cylinder as it is pulled in. This rotational

force is sometimes increased by having a helical induction

port passage where the air is guided into a semi-vortex swirl

around the valve stem on its way into the cylinder.

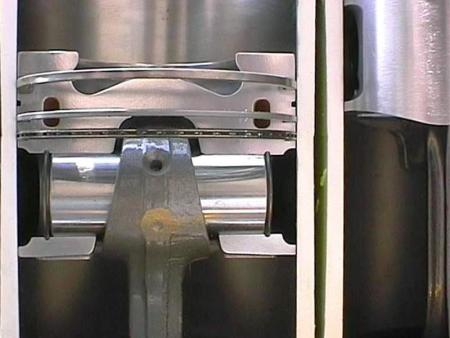

The piston has a bowl in its crown. As the piston approaches

the top of the cylinder the rotating air is forced into the

piston bowl. The rotational force is magnified by the reduced

diameter of the piston bowl. Thin, deep bowls have a higher

swirl rate.

At the same time air squish is initiated as the air is forced

from above the piston crown in towards the centre of the piston.

The squish forces meet at the centre of the cylinder and oppose

each other being forced downwards into the bowl where they

follow the bowl profile being led into a horizontal swirl.

Simple bowl showing squish action - also described as torodial.

In order for the fuel and air to mix the fuel injection is

set to spray against the wall of the piston bowl. The drag

created by this contact stops the combusting fuel spray being

dragged with the swirl and allows the fuel to contact with

fresh oxygen. With thin bowls the spray does not have to penetrate

as far to reach the combustion chamber wall so a wider more

fine injection can be utilised that will mix more readily

with the fuel.

With the quickest engines large air movement is required

to give a fast mix. The fuel spray has to be more penetrating

to overcome the increased air forces and the injection event

rate is increased so that the fuel charge is swiftly delivered

and has longer to mix and combust.

A trick used by several engine manufacturers is to give the

bowl a lip to prevent the air squish motion pushing fuel above

the piston crown, so that the majority of the fuel charge

is mixed and burnt within the bowl. The lip also creates further

micro turbulence within the bowl. Engines with this re-entrant

lip design include VW/Audi tdi engines (thanks to John O for

this info), Perkins Prima, Perkins 42482 and some Isuzu square

(when looking from above) bowl chambers. The square chamber

produces micro turbulence from its rounded corners which provide

superior air-fuel mixing.

Perkins Squish Lip Re-Entrant Bowl Piston

Isuzu Square Bowl Piston

Chevy Duramax Piston (Cheers JMJ)

The Elsbett Piston

The Elsbett engine has a deep bowl which has a slight lip.

The main difference is that the fuel charged is injected in

such a manner as to 'blend perfectly with the air' and combust

within a central core of hot air, not contacting the chamber

walls, which is necessary for good air/fuel with other designs

examined.

The MAN M system (film) combustion chamber

A similar shaped piston bowl to the Elsbett

system. With this design the fuel is injection is directed

onto the chamber wall where it spreads as a film, combusting

as the film evaporates due to the heat of the piston. The

heat of the piston has to be within a temperature range to

achieve fuel evaporation without causing thermal decomposition

and carburizing of the fuel.

Lessons to be learnt for Veg Oil

To summarise I would presume:-

Quick injection rate gives more time for the oil to begin

to combust.

Chamber shapes that create greater micro turbulence - the

Isuzu square chamber would appear superior in this respect

- should provide better fuel air mixing and faster combustion.

Deep re-entrant chambers should be more effective than shallow

chambers.

Comments, suggestions or observations will be gratefully

received from those with relevant experience or information.

http://biodiesel.infopop.net/2/OpenTopic?q=Y&a=tpc&s=465094322&f=166094322&m=7283049396&p=3

http://www.elsbett.com/gd/eteche.htm

http://www.elsbett.com/gd/etech.htm

http://www.univ-orleans.fr/ESEM/LME/Commun/Doc/pdf/21Resume1.pdf

'Advanced Engine Technology' by Heinz Heisler ISBN 0-340-56822-4

|