Version 2.0 (17/4/2004)

1 The Diesel Engine

2 Theory of Vegetable Oil Use as

a Fuel

3 Engine suitability

4 Heating the Oil

5 Biodiesel

6 Micro Emulsions and Blends

7 Vegetable Oil Engine Design

8 Vegetable Oil Furnaces and Heaters

9 Oil Types and Filtering

10 Taxation

11 Implications of Vegetable

Oil Fuel Use

12 Sources

The Diesel Engine

Dr. Diesel

The term diesel derived from a German engineer, Dr Rudolph

Diesel, who is widely credited with developing the compression

ignition (CI) engine. In 1892 he took out a patent (no.7241)

on a CI engine which ran on coal dust this was built in

1893 but exploded when it was run.

In 1894 he filed a patent for a CI oil engine which he

successfully ran in 1897. In 1900, at the world fair in

Paris, a small diesel engine was demonstrated running on

peanut oil. The Otto Company provided this demonstration

at the request of the French Government which was keen to

use peanut oil as an energy source for its African colonies.

There is however some controversy as to weather he was

the inventor of this type of engine as a British engineer,

Herbert Ackroyd-Stuart took a patent (No.7146) in 1890 for

an oil fired engine which was the result of development

he had been doing on low-compression oil engines. This patent

describes "first of all compressing the necessary quantity

of air for the charge, and then introducing into this quantity

of compressed air the necessary supply of combustible liquid,

vapour or gas, to produce the explosive mixture." The

engine was in production in 1892. Also Ruston & Hornsby

Ltd claimed, in a 1937 advertisement “Before Dr. Diesel

took out his first oil engine patent, we were making successful

oil engines at our Granthan Works.”

As the engine could be fuelled on a variety of oil fuels,

Dr. Diesel saw his engine as a way of freeing small producers

from the grip the steam industry had on the energy markets

of the time. He worked on the development of the engine

until his untimely death. Much controversy surrounds his

death on board a boat to England some say he committed suicide,

others suggest an accident, others still that something

more sinister was afoot.

Due to economics fossil oil became the energy sources of

choice for the developed nations and a distillate of crude

that was suitable for CI engines came to be known as diesel

fuel. CI engine development since this time has largely

been with diesel fuel in mind. Most CI engines are engineered

to optimise the burning of this fuel. It is however possible

to tune these engines so that they can be fuelled with vegetable

oil.

C.I. Engine Basic Principles

Diesel engines come in all shapes and sizes with refinements

made to the basic principles developed in the late 19th

century.

The Direct Injection Engine (DI)

The engine uses the heat caused by compressing air in a

cylinder, with a piston, to ignite fuel oil which is injected

into the cylinder. This oil burns and creates an increase

in pressure which forces the piston back down the cylinder,

providing the power. The burnt gasses are exhausted from

the cylinder and replaced by fresh charge through valves,

commonly positioned above the piston in the cylinder head.

The fuel oil is pushed into the engine under high pressure

at the correct time by an injector pump. The oil is sprayed

into the engine cylinder as a very fine mist from the nozzle

of an injector. The fine fuel oil mist readily mixes with

hot air in the cylinder, ignites and provides an efficient

burn. The injector pump also meters the amount of fuel delivered.

The more fuel the more power/faster the engine.

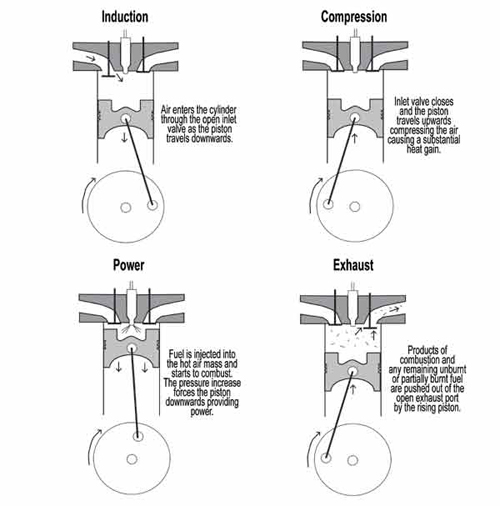

Operating cycle of the common four stroke engine –

the engine provides one combustion event during the four

piston strokes illustrated.

Large DI Engines

Large slow running DI engines (under 1500 rpm) commonly

used to power machinery and large boats have 'open chambers'

where the piston has a wide shallow dish in the centre of

its upper surface. Air movement within the combustion chamber

is minimal and the multi-hole injectors (often 8-12 holes)

are set to inject a fine mist into the dish. Due to the

size of the combustion chamber and the distribution of fuel

sufficient air is present to supply the fuel with sufficient

oxygen and the fuel combusts before it contacts surfaces

of the combustion chamber.

Small DI Engines

Small high speed direct injection engines

have a deep hollow in the top of the piston which contains

most of the air when the piston is at the top of the engine.

As air is drawn into the engine a swirling motion is initiated.

The air is forced into a horizontal rotary motion by the

design of the air inlet port or valve. Some engines have

a helical or partial vortex form of inlet port to encourage

the swirl in others the inlet valve is partially masked

to initiate the desired motion. As compression of the air

begins it is forced or squished into the specially shaped

piston hollow which initiates a vertical swirl achieving

ever increasing speeds and heat as the air is compressed.

These combined movements create an air vortex within the

piston into which the fuel is injected. The fuel spray,

finely atomised by the high-pressure injector, passes through

this air vortex where it is provided with sufficient oxygen

and heat to combust. DI engines generally utilise a multi-hole

injector to provide a good distribution of fuel.

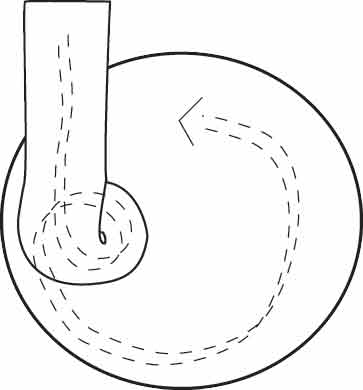

Squish air motion in a DI engine

Air spiralling through a helical intake

into engine cylinder

Photo: Bosch

Cut away view of a

small DI cylinder

The Indirect Injection Engine (IDI)

A later development was the IDI engine that utilises a

separate combustion chamber, connected to the engine cylinder,

into which the fuel is injected and combustion is initiated.

A heat resistant insert with low heat conductivity is located

within the combustion chamber so it quickly heats up and

retains heat from combustion, providing extra heat to enable

quicker ignition. The fuel is injected into the hot combustion

chamber as a jet at a low pressure compared to the fine

high-pressure spray of a DI engine. The fuel jet hits the

hot insert where ignition is initiated; the fuel is distributed

around the combustion chamber as combustion continues. The

expanding burning fuel, along with partially burnt and unburnt

fuel, is carried into the hot engine cylinder where further

oxygen is available and combustion continues.

The most common prechamber format utilised is the Ricardo

Comet design developed by Ricardo and Company of Shoreham,

Sussex, UK. With this design air is pushed from the cylinder

into a circular ‘swirl chamber’ through a tangentially

aligned throat. The bottom half of the chamber along with

the throat is constructed from a nimonic alloy designed

to maintain high temperatures during engine operation. The

temperature of the compressed air is raised further while

passing through the throat. A vigorous swirl motion is initiated

as the air is forced into the circular swirl chamber. The

fuel is injected into the swirl chamber and rapidly atomised

within the mass of hot turbulent air.

Photo:Bosch

IDI engine – Picture shows fuel being injected into

a swirl chamber with a heated glow plug – not shown

is the throat from the engine cylinder to the swirl chamber

- Note the lower half of the chamber constructed from nimonic

alloy.

Mercedes IDI engines utilised a different design in which

a jet of fuel is fired at a ball like baffle surface. The

jet is broken by the baffle surface and distributed around

the prechamber being finely dispersed by the turbulent air

charge. Upon combustion the fuel/air mixture is carried

through several bores into the main engine cylinder. Mercedes

later improved this design, reshaping the prechamber, creating

a swirling air motion to improve combustion.

The advantage of IDI engines is that they can operate at

higher engine speeds as the more efficient fuel and air

mixing provides faster combustion. Cars and small commercial

vehicles require a small, light engine which must be able

to operate at higher speeds to provide the necessary power,

with the advent of the IDI engine the use of diesel engines

in such vehicles became widespread.

The heat lost due to the increased surface areas of the

combustion chamber and the pressure drop between cylinder

and combustion chamber make it necessary for the engines

to operate at higher compression ratios to provide enough

heat for ignition. The lost heat and force required to push

the air into the combustion chamber is wasted energy making

IDI engines around 10-15% less efficient than DI units.

IDI engines became the engine of choice in small vehicle

applications as a small engine could produce more power

at higher speed providing a suitable power/weight ratio

for such applications. Recent advances in fuel injection

technology, which provide more precise fuel delivery, allow

faster combustion within a DI engine. The improved efficiency

of the DI cycle has spurred the fitment of such engines

to become more common in small vehicles.

Fuel Injection Equipment

Timing, pressure and quantity of fuel delivery are crucial

for efficient combustion. The important task of fuel delivery

is performed by the fuel injection equipment.

Mechanically Controlled Fuel Injection

Fuel is supplied to the injector by an injector pump.

The injector pumps are mechanically driven from the crankshaft.

The drive from the crankshaft is set so that the injector

pump delivers fuel at the correct time in the engine operation

cycle.

Single Element Injection Pump (Jerk Pump)

The simplest type of injection pump found on single cylinder

engines. The single pumping element delivers fuel to the

injector via a high pressure pipe. Multi-cylinder engines

sometimes utilise multiple single element pumps. This is

most often seen in stationary or marine applications.

In-Line Injector Pump

In-line pumps use a similar design to the single element

pump, for a multi-cylinder engine. A number of jerk pumps

are combined into a single component. The pumps are driven

by a camshaft held within the pump body.

Rotary Injector Pump

Rotary pumps are similar in appearance to a petrol engine

distributor. A single pumping mechanism rotates and supplies

fuel to each cylinder in turn.

Electronically Controlled Fuel Injection

Recently developed electronically controlled injectors can

provide exacting amounts of fuel at very high pressure,

very precise timing and even multiple injections within

each cycle to give greatly improved combustion and in turn

increased fuel economy and lower engine noise and toxic

emissions. Both in-line and rotary injection pumps have

been developed with electronic components to help achieve

more accurate injection timing and metering. By monitoring

the engine using a number of sensors the electronic controller

can modify the fuel injection characteristics to improve

combustion.

Common Rail Injection Systems (CDI)

With this system a pump constantly supplies fuel at a

very high pressure to the common rail - a tube with thick

walls. From the common rail fuel is supplied to electronically

controlled injectors.

The higher pressure injection gives a finer spray and improved

combustion.

Unit Injector System and Unit Pump Systems

Unit injector systems combine the pump and injector into

one unit. The pump is driven from the engines camshaft.

Fuel delivery is timed and metered by electronically controlled

valves. Unit pump systems are similar with the pump and

injector separated and connected by a short high pressure

fuel line.

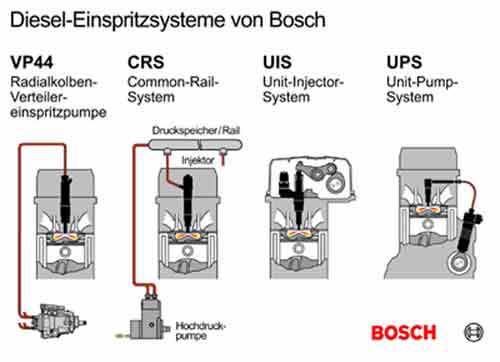

Diagram: Bosch

Bosch Electronic Injection Systems:

Illustration shows a VP44 electronically controlled rotary

pump and 3 other systems

Turbocharger

Diesel engines are particularly suited to turbocharging.

Turbochargers use a specially designed turbine and centrifugal

compressor linked by a shaft to utilise the energy of the

exhaust gas being forced from the engine to compress extra

air into the engine. The compressed air contains more oxygen.

The amount of fuel that can be effectively combusted is

directly proportionate to the amount of oxygen within the

engine. Thus the maximum fuel delivery can be adjusted and

engine power increased by as much as 60%. Due to more efficient

combustion fuel efficiency is improved by about 10%. Turbocharged

engines are generally of a more rugged construction to withstand

the greater forces and temperatures encountered.

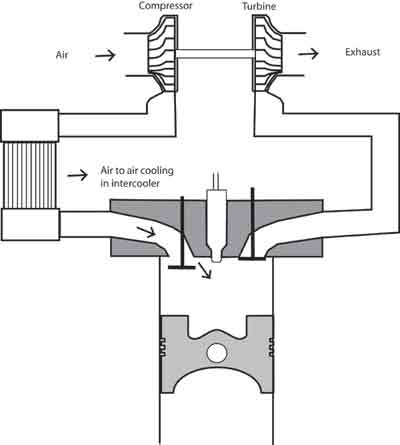

Intercooler

Intercoolers are often added to turbo engines to cool

the air charge between the turbocharger and the engine.

Compression of the air and proximity to the hot exhaust

gases increase the temperature of the air charge and cause

it to expand. The intercooler, most often an air to air

heat exchanger, uses air flow in the same way as an automobiles

radiator to bring the temperature of the air charge down.

The cooled air contracts and more of it – and thus

more oxygen – can be forced into the engine cylinder.

Turbocharged and intercooled engine.

Combustion in a Diesel Engine with Mechanical Fuel Injection

System

The combustion process is initiated when the fuel is injected

into hot air within the combustion chamber. The temperature

reached in the combustion chamber will be effected by;

compression ratio : the more the air is

compressed the higher the pressure and the hotter it becomes

the speed of the engine : the faster the

air is compressed the less time there is for heat to be

lost from the combustion chamber and air to seep by the

piston rings reducing the pressure.

the temperature of the incoming air

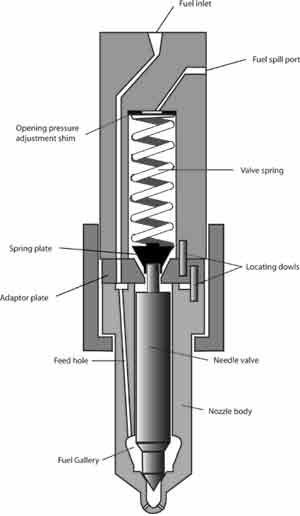

The fuel is delivered by the injector pump pushing fuel

through the injector. The pumping action produces a rise

in pressure in the fuel line as the pressure rises it overcomes

a spring which holds the injector needle valve closed. The

injection lag is the time between the pump pumping and the

fuel being delivered and is affected by the length of the

high pressure injection pipe, the load on the injector spring

and the density and thus compressibility of the fuel.

The fuel is injected into the hot air mass

within the combustion chamber by the injector which delivers

a fine spray of fuel. This spray breaks into small droplets

which begin to evaporate in the intense heat. Each droplet

becomes surrounded by a layer of vapour which begins to

react with the surrounding oxygen. For any delivered amount

of fuel, the finer the spray, the larger the surface area

of fuel available to vaporise and then react with oxygen.

However a fine spray will not penetrate far into the combustion

chamber where further oxygen would be available and would

be easily dragged around with any air flow which would otherwise

be introducing further oxygen. A spray of large droplets

would travel further through the combustion chamber less

affected by air motion but would take longer to ignite and

longer to combust entirely.

Multi Hole Injector

The oxidation process creates heat which causes more vaporisation

and increased oxidation until the self-ignition temperature

of the fuel is reached and, at a limited number of points

within the chamber, ignition of the vapour begins. The time

between the fuel being introduced and start of ignition

is called the ignition lag or delay period.

Combustion then spreads quickly through the fuel which

has been injected during ignition lag causing a rapid pressure

rise. A long ignition lag allows a greater amount of fuel

to be delivered which will cause a more rapid and greater

pressure. The increased engine noise and rough running ,known

as diesel knock, is a direct result of these greater pressures.

The rate of burn will depend on the speed at which the vaporising

fuel droplet can come into contact with unreacted oxygen.

The speed of the fuel and motion of the air, if any, affect

the burn rate. The rapid pressure rise continues, slowing

as the temperature increases to a level where fuel droplets

are burnt soon after being injected.

At each fuel droplet the liquid oxidation reaction of

the vapour will continue rapidly as long as sufficient oxygen

is available. As the combustion continues less oxygen is

available close to the injector and the fuel droplets take

longer to find enough oxygen to burn. Combustion continues

at a steady level until the fuel delivery is completed.

The remaining fuel and unburnt products of the oxidation

reaction continue to burn with decreasing vigour as the

temperature in the chamber falls. Some of these products

remain unburnt and are largely expelled with the exhaust.

1 The Diesel Engine

2 Theory of Vegetable Oil Use as

a Fuel

3 Engine suitability

4 Heating the Oil

5 Biodiesel

6 Micro Emulsions and Blends

7 Vegetable Oil Engine Design

8 Vegetable Oil Furnaces and Heaters

9 Oil Types and Filtering

10 Taxation

11 Implications of Vegetable

Oil Fuel Use

12 Sources