Oil Types and Filtering

1 The Diesel Engine

2 Theory of Vegetable Oil Use as a Fuel

3 Engine suitability

4 Heating the Oil

5 Biodiesel

6 Micro Emulsions and Blends

7 Vegetable Oil Engine Design

8 Vegetable Oil Furnaces and Heaters

9 Oil Types and Filtering

10 Taxation

11 Implications of Vegetable Oil Fuel Use

12 Sources

Oil Properties

Certain characteristics of a given oil or fat will affect its suitability for use as a fuel. The design of a SVO system, along with ambient temperatures of operation, requires consideration when selecting a fuel oil.

Melt Point (MP), Cloud Point (CP) and Pour Point(PP)

Almost all oils and fats are made primarily from a mixture of different triglycerids, these are made up from a molecule of glycerin linked to three fatty acids (FA), which solidify at different temperatures. As the oil is cooled towards its melt point (freezing point or pour point) the different triglycerids solidify in turn causing the oil to become cloudy and increasingly thick before it finally solidifies completely.

The temperature at which an oil starts to solidify is known as the cloud point.

Solid triglycerid particles in a flowing oil will get caught in a fuel filter and will eventually block (wax) it.

When the temperature drops to the oils melt point the oil will become solid and no longer flow and block any fuel system components in which it lies.

When operating an engine at temperatures below an oils cloud point fuel heating will be necessary in or upstream of the fuel filter to avoid waxing. In temperatures below melt point the entire fuel system including all fuel lines and fuel tank will need to be heated.

Flash Point (FP)

The temperature at which an oil starts to evaporate giving off gases that can be ignited.

Iodine Value (IV)

Many vegetable oils and some animal oils are described as 'drying' or 'semi-drying'. These oils gradually react with oxygen in air and polymerise into a plastic like solid, for this reason these oils are used as a base for paints. This reaction is increased inside an engine and can lead to quick formation of deposits.

Iodine Value (IV) is a value of the amount of iodine, measured in grams, absorbed by 100ml of a given oil. The higher the IV the greater potential the oil has to polymerise.

Viscosity

The thickness of an oil. Viscosity is determined by measuring the amount of time taken for a given measure of oil to pass through an orifice of a given size

Cetane Number (CN)

Is a measure of an oils combustibility under compression. The higher the CN the greater its combustibility. The slower an engines speed, the lower the CN of a fuel on which it will operate. Large low speed engines can operate on a fuels with a CN as low as 20, some high-speed passenger car diesel engines specify 55 CN fuel. [12]

Calorific Value, Heat of Combustion (HG)

The energy released upon an oils combustion

Density

Determined by weighing a given measure of oil. Oils that are more dense will contain more energy. For example petrol and diesel fuel give comparable energy by weight but diesel is denser and gives more energy per litre.

Vegetable Oil

Vegetable oils come in different thickness from solid vegetable lard to very light linseed oil. There can be a difference between oils from different verities of the same plant and the processing of the oil will effect the form.

Animal Fats

Animal fats are often solid at ambient temperatures (hence a fat). All forms of animal fat, tallow and oil can potentially be used as a fuel.

Waste Oils

Waste oils that have been used for cooking can be utilised as a fuel. Used oil often becomes thicker due to hydrogenation and will contain vegetable or animal fats from the foodstuffs which it has been used for cooking. It does have the advantage of being a readily available waste product. Thorough cleaning is necessary to remove food particles or other contaminates that would quickly block fuel filters or damage the engine fuel system. The injector pump is an expensive fuel system component which is particularly susceptible to damage from the ware of small particles due to its fine construction and tolerances.

Contamination and 'quality' of waste oil varies considerably. Some caterers will change their oil regularly, other oil may be reused for some time, becoming thick due to increased hydrogenation and contamination of the oil. All types of contaminates can be present in waste oils.

Waste Vegetable Oil (WVO)

These waste oils have traditionally been used as a component of animal feeds although this is falling out of favour due to cases of contaminated oil entering the animal food chain and causing public health problems. Oil recyclers either charge to take oil away or provide fresh supplies at an inflated price to cover costs. The cost of disposal means that much cooking oil is disposed of down drains where it causes problems with blockages when it solidifies on cooling. Large amounts of oil also end up in landfill sites.

Fuel-related properties and iodine values of various fats and oils

| Oil or Fat |

Iodine Value |

CN |

HG (kJ/kg) |

Viscosity (mm2/s) |

CP (°C) |

PP (°C) |

FP (°C) |

| Babassu |

10-18 |

38 |

|||||

| Castor |

82-88 |

? |

39500 |

297 (38°) |

--- |

-31.7 |

260 |

| Coconut |

6-12 |

||||||

| Corn |

103-140 |

37.6 |

39500 |

34.9 (38°) |

-1.1 |

-40.0 |

277 |

| Cottonseed |

90-119 |

41.8 |

39468 |

33.5 (38°) |

1.7 |

-15.0 |

234 |

| Crambe |

93 |

44.6 |

40482 |

53.6 (38°) |

10.0 |

-12.2 |

274 |

| Linseed |

168-204 |

34.6 |

39307 |

27.2 (38°) |

1.7 |

-15.0 |

241 |

| Olive |

75-94 |

||||||

| Palm |

35-61 |

42 |

|||||

| Peanut |

80-106 |

41.8 |

39782 |

39.6 (38°) |

12.8 |

-6.7 |

271 |

| Rapeseed |

94-120 |

37.6 |

39709 |

37.0 (38°) |

-3.9 |

-31.7 |

246 |

| Safflower |

126-152 |

41.3 |

39519 |

31.3 (38°) |

18.3 |

-6.7 |

260 |

| High-oleic safflower |

90-100 |

49.1 |

39516 |

41.2 (38°) |

-12.2 |

-20.6 |

293 |

| Sesame |

104-120 |

40.2 |

39349 |

35.5 (38°) |

-3.9 |

-9.4 |

260 |

| Soybean |

117-143 |

37.9 |

39623 |

32.6 (38°) |

-3.9 |

-12.2 |

254 |

| Sunflower |

110-143 |

37.1 |

39575 |

37.1 (38°) |

7.2 |

-15.0 |

274 |

| Tallow |

35-48 |

- |

40054 |

51.15 (40°) |

- |

- |

201 |

| Diesel No.2 |

47 |

45343 |

2.7 (38°) |

-15.0 |

-33.0 |

52 |

|

| Oils and their melting points and Iodine Values |

||

| Oil |

Approx. |

Iodine Value |

| Coconut oil |

25 |

10 |

| Palm kernel oil |

24 |

37 |

| Mutton tallow |

42 |

40 |

| Beef tallow |

- |

50 |

| Palm oil |

35 |

54 |

| Olive oil |

-6 |

81 |

| Castor oil |

-18 |

85 |

| Peanut oil |

3 |

93 |

| Rapeseed oil |

-10 |

98 |

| Cotton seed oil |

-1 |

105 |

| Sunflower oil |

-17 |

125 |

| Soybean oil |

-16 |

130 |

| Tung oil |

-2.5 |

168 |

| Linseed oil |

-24 |

178 |

| Sardine oil |

- |

185 |

Iodine Numbers of Common Fats* |

|

Fat or Oil |

iodine number |

| Linseed oil |

173 - 201 |

| Tung Oil |

170.6 |

| Menhaden oil |

139 - 173 |

| Whale oil |

121 - 146.6 |

| Soy bean oil |

137 - 143 |

| Sunflower oil |

119 - 135 |

| Corn oil |

111 - 130 |

| Cottonseed oil |

108 - 110 |

| Sesame oil |

103 - 108 |

| Rapeseed oil |

94 - 102 |

| Peanut oil (arachis) |

83 - 100 |

| Olive oil |

79 - 88 |

| Horse oil |

71 - 86 |

| Lard |

46 - 70 |

| Palm oil |

51.5 - 57 |

| Milk fat |

26 - 50 |

| Beef tallow |

38 - 46 |

| Mutton tallow |

35 - 46 |

| Cacao butter |

32 - 41 |

| Palm kernel oil |

13 - 17 |

| Coconut oil |

8 - 10 |

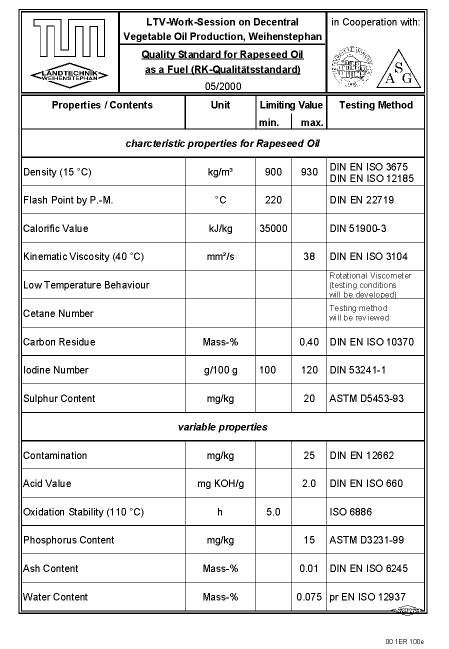

German Rapeseed Fuel Standard

In Germany a standard exists for rapeseed oil fuel. The standard was proposed by The Bavarian National Institute for Agricultural Engineering and The Technical University of Munich Weihenstephan.

Manufacturers of vegetable oil engines, oil mill operators and scientists agreed on the standards. The aim was to allow for provision of a standard oil fuel which would allow for reliable operation of vegetable oil engines in vehicles and to serve as basis for future engine developments

Processing Oils

Cleaning Oils

Settling

Contaminates will settle to the bottom of oil when left to stand. The process works better in warm conditions and over a number of days or weeks. Oil free of the heaviest contaminates can be drawn from the settling vessel ready for filtering

Filtering

Filtering an oil will remove contaminates. Heating an oil will allow quicker filtration but also allow oil components with a higher melt point through the filter.

Filtration through a number of increasingly fine filters may well be required depending on contaminate levels. Using a mesh to catch the largest contaminates, followed by a course filter and finally a fine filter equal to or greater than the rating of the engine diesel fuel filter will provide a fuel with acceptable levels of contaminates. Various methods could be used to suit requirements.

Filter Ratings

Filters are often rated in microns (one millionth of a meter, or micro-meter). This is a rating of what sized particles will not pass through a filter medium. This is however quite an inconsistent rating as there is no standard test. Different types of contaminate will pass through different filter materials at different rates in different operating conditions.

A new rating the beta (B) ratio is being slowly introduced this is a more complete assessment of a filter that is carried out to a strict procedure (thus it's slow uptake) giving comparable results. A number of different B ratios are given, a B20 ratio of 2 means that one of every two particles above 20 microns is let through, a B5 of 4 means one of every 4 particles above 5 microns and so on. B ratios only go up to 75(giving the filter a 98.67% efficiency) because of the way the test is preformed. A filter would stop larger particles altogether.

Water Washing

Sugars, salts and larger food particles can be pulled out by mixing with water and then draining the oil after allowing the mixture to settle and separate. Heating the oil and water aids this process.

Centrifuge

A centrifuge utilises centrifugal force to separate out impurities in an oil. Denser impurities are thrown to the outside of the centrifuge leaving clean oil in the centre. Centrifuges for cleaning lubricating oil are available which remove all but very small contaminates.

Winterising OilsOils are often winterised so that they will not cloud when they are cooled as this characteristic has proved unpopular with consumers. The winterisation process involves slowly bringing the oil down to the lowest temperature at which it will be used. It is then allowed to stand undisturbed at that temperature for a long period to allow the solidified triglycerids to separate from the liquid oil. The oil is then filtered to remove the solidified material.

Processing of Raw Vegetable Oils

Vegetable oil is primarily extracted from nuts, seeds and fruit. Either fruits are boiled, nuts and seeds crushed or the oil is extracted by use of the solvent such as hexane. Extracted oils contain impurities some of which it may be necessary to remove before the oil can be reliably utilised as fuel.

Degumming Oils

Raw oil is often degummed. This process is common with oils that contain high levels of phospholipids. The degumming process removes gummy substances and other impurities from the oil.

The degumming process can be carried out by use of a number of different methods. Adding 2-3% water, heating the mixture to 50 deg C and agitating the mixture then allowing the hydrated phospholipids to settle is the simplest method. More ensured results are obtained by using phosphoric or citric acid instead of water, and it is this process that is preferred on a commercial scale. The use of citric acid gives more acceptable effluent.

Fatty Acid Removal

Free fatty acids are removed, simply, by saponification. This is by mixing with strong aqueous caustic soda, often under heat, forming a soap that is allowed to separate from the fat. Other methods are used commercially.

1 The Diesel Engine

2 Theory of Vegetable Oil Use as a Fuel

3 Engine suitability

4 Heating the Oil

5 Biodiesel

6 Micro Emulsions and Blends

7 Vegetable Oil Engine Design

8 Vegetable Oil Furnaces and Heaters

9 Oil Types and Filtering

10 Taxation

11 Implications of Vegetable Oil Fuel Use

12 Sources

© All original material on this website is copyright Darren Hill, unless otherwise stated, and may be copied and distributed for non-commercial purposes only as long as the source of the material is stated and a reference to the vegburner website URL is included (http://vegburner.co.uk/). All material is provided "as is" without guarantees or warranty of any kind, either expressed or implied.