Engine

Suitability

Version 2.0 (20/4/2004)

Engine Suitability-Version

1.0

1 The Diesel Engine

2 Theory of Vegetable Oil Use as a

Fuel

3 Engine suitability

4 Heating the Oil

5 Biodiesel

6 Micro Emulsions and Blends

7 Vegetable Oil Engine Design

8 Vegetable Oil Furnaces and Heaters

9 Oil Types and Filtering

10 Taxation

11 Implications of Vegetable Oil

Fuel Use

12 Sources

Engine Suitability

There are many variations on diesel engine

design. Various design elements effect suitability for vegetable

oil fuel use.

Combustion Chamber

Direct Injection (DI)

Problems can occur with deposits building within

DI engines when running on vegetable oil. The design of the

combustion chamber and the injector along with their positioning

will affect suitability

The Elsbett DI multifuel engine [34] [35] produced

from the 1970s could be fuelled with vegetable oil or diesel.

This engine has a deep, almost spherical, combustion chamber

within the piston. The injector nozzle protrudes into the

cylinder and delivers fuel directly to the centre of the combustion

chamber. The unique design ensures that fuel is burnt without

contacting the combustion chamber walls.

Fuel oil with a substantially greater viscosity will cause

degraded atomisation from injectors that are deigned for a

thinner fuel. Combustion will be adversely affected causing

an increase in emissions and giving a greater potential for

harmful deposits on the injectors and within the combustion

chamber.

Hemmerlein et al.[28] tested three unmodified

DI engines, one 2.6 litre air cooled and two larger, 6.6 litre

and 12 litre, turbo charged and intercooled with liquid cooling,

running rapeseed oil. All three engines failed durability

tests due to problems caused by carbon build ups.

Karaosmanoglu et al.[30] tested a Panccar Motor

1 litre single cylinder DI engine running sunflower oil. The

engine successfully completed long-term engine testing when

it was started and shut down for 5 minutes with diesel fuel.

The engine was run at a constant low speed under partial load.

Both Pflanzenoeltechnik-Nord GmbH [49] and Albrecht Transporte

[50] report up to 250,000 km travelled using vegetable oil

in a number of different modern DI trucks.

DI engines with a re-entrant bowl type combustion chamber

- where the bowl has a lip around the top to encourage fuel

to stay within the combustion chamber, away from the cylinder

walls and piston rings – should have lower frequencies

of ring land fouling associated problems. The lip of a re-entrant

bowl also causes micro turbulence within the chamber, which

aids fuel/air mixing and thus gives superior combustion.

Deeper combustion chambers, which are generally

of a smaller diameter give rise to increased swirl which aids

atomisation and injection pressure can be set higher as the

fuel does not have to penetrate as far to reach the combustion

chamber walls (which allows wall wetting and proper combustion).

The increased squish area of this design gives a larger overall

surface area and a greater output of hydro carbons due to

heat loss.

Indirect Injection (IDI)

The fuel is injected as a jet and atomised

in a separate combustion chamber before it enters the cylinder

and completes combustion. The atomisation processes, caused

by high air speeds, within the annexed combustion chamber

after injection along with the remoteness of injection from

the piston rings make these units less prone to problems from

using thicker fuel oil.

Hemmerlin et al. [28] tested three unmodified

IDI engines running on rapeseed oil. A small 1.6 liter swirlchamber

engine failed durability testing due to carbon build up within

the engine. Two larger IDI engines, a 6.2 litre prechamber

engine and a 5.7 litre swirlchamber engine completed the durability

testing.

Fuls et al.[31] found that an unmodified Caterpillar

IDI engine in a tractor successfully completed extended service

tests using sunflower oil as a fuel. This test led to Caterpillar(South

Africa) providing a warranty on this engine running this fuel.

Togashi et al. [29] found that a small Yanmar IDI engine could

be reliably operated on refined or deacified rapeseed oil.

Niegsch [10] found a Mercedes prechamber engine

can be operated on refined, food grade rape oil for over 200,000

km with only minor problems.

Injector Pump (IP)

Mechanical Injection

In-Line Pump

These pumps have proved to be very reliable

when fuelled with vegetable oil fuels. Mercedes IDI engines

with in-line pumps have been run, without modification, fuelled

with rapeseed oil for extended periods.

Rotary Pumps

The single pumping mechanism which pumps fuel

to all cylinders has to work harder than its in-line equivalent.

On a four cylinder engine the pump mechanism is pumping four

times to every one pump of an in-line. The increased stress

on the pumping mechanism, of pumping more viscous fuel, is

multiplied.

Rotary pumps generally contain a sliding vane

type transfer pump to supply a constant excess of fuel at

pressure to the injector pump.

There are also two common designs of rotary pump mechanisms

Bosch Type: The entire rotating valve system moves backwards

and forwards pumping the fuel.

Lucas/CAV Type: Uses two plungers that are flung outwards

by the rotor, they are pushed inwards by a cam to expel the

fuel.

The Lucas/CAV units has been found to be susceptible to malfunctions

when running on vegetable oil, thought to be caused by their

less rugged construction and possible accumulation of dirt,

held by centrifugal force, within the plunger cylinders which

would be cleared by the backwards and forwards pumping motion

of the Bosch unit.

The Lucas/CAV units come with either metal or fibre vanes

in the transfer pump which pulls the fuel into the IP. Transfer

pumps have been damaged, examination of damaged pumps has

lead to the conclusion that the damaged was caused by the

increased heat created pulling thicker fuel or a swelling

of fibre vanes, metal vanes can be fitted to alleviate this

possible problem. Another possible cause of problems is expansion

or contraction caused by fuel of a radically different temperature

suddenly being introduced. Great care should be taken when

using this type of pump. The fuel should be filtered very

thoroughly and vegetable oil heated carefully.

If an engine is to be started with cold (thick) oils it

is advisable to keep the engine speed low until the oil has

been heated to reduce stresses on the pumps, this is especially

the case with rotary pumps.

Injector pumps have been modified to allow them to function

more reliably with vegetable oil. Lucas/CAV rotary pumps can

have fibre vanes up rated. The main pumping mechanism(s) within

an IP can be modified by the use of lapping paste on the pump

plunger(s) so that it requires a similar force to move when

pumping SVO as when using diesel or channels can be cut into

the rotor in a rotary pump to increase lubrication and reduce

heat. This will reduce stresses on the pump but in many cases

may be unnecessary. Injector pumps are very precise systems

and modifications should only be undertaken by a suitably

experienced engineer.

Electronic Injection

The more precise injection controls and higher injection

pressures of new electronically controlled systems are capable

of providing superior combustion. However equipment may need

tuning to run vegetable oil fuels. Injection events are governed

by computers, which monitor a number of different factors

to give the best combustion performance. The properties of

vegetable oil based fuels have the potential to confuse the

computer as the fuel may have properties that may be outside

the parameters expected by the computer or under a given injection

program the fuel may behave differently to how the computer

expects and not combust effectively. Damage to sensing equipment

is also possible.

Owen [36] reported a damaged incremental angle sensor within

a Bosch VP44 injector pump fitted to an Vauxhall Astra Diesel

Tdi while running 80% recycled used vegetable oil, 10% industrial

methylated spirits (denatured ethanol), 5% butanol and 5%

petrol mix.

Cummins [37] reported, “There are confirmed accounts

of ISB engine fuel pump failures due to the effects of alcohol

induced de-lamination of an internal timing sensor component.

Robert Bosch, the fuel pump manufacturer prohibits alcohol

blended fuel in the VP44 fuel pump on the ISB/QSB Cummins

engine."

Frei [38] described modifications to a Mercedes Sprinter

CDI (common rail). The engine would not start on vegetable

oil when the engine was warm. The engine control computer

monitors engine temperature when starting. Injection quantity

is reduced when starting with a warm engine. The computer

had to be tricked to think that the engine was cold starting

so that it increased the fuelling and enabled initial combustion.

Burton[51] reported that Elsbett engineer Alexander Noack

from Elsbett used a laptop to reprogram the onboard computer

so that it would think that the engine is cooler than it is

and heat the glow plugs for a longer duration – allowing

for smooth starts with vegetable oil.

Injectors

Pilot Injection

Injection systems are increasingly being designed with a

pilot injection. A small quantity of fuel is introduced before

the main fuel load is injected. Ignition of this fuel commences

and ‘conditions’ the combustion chamber, providing

heat that reduces the ignition delay of the main fuel load.

Some electronically controlled injection systems provide

the pilot fuel as a separate injection. High-speed fuel delivery

control solenoids allow multiple injections of fuel during

the fuel delivery phase. The ferocity of the main combustion

event is reduced as less fuel is delivered during the now

reduced ignition lag period of the main fuel load.

Fuel introduced during the ignition delay or lag period,

which is the time between fuel being introduced to the combustion

chamber and conditions becoming correct for ignition to commence,

combusts quickly, the larger the amount of fuel present at

the onset of ignition the greater the noise.Ignition lag is

increased with cold engines and at low engine loads, as less

heat is available within the engine and combustion begins

later. The fuel properties and quality of atomisation also

effect ignition lag. Ignition lag is the cause of ‘diesel

knock’ or ‘clatter’.

Injectors with a pilot injection function were introduced

to reduce engine noise by reducing the amount of fuel injected

during the ignition lag period.

Experiments using a shock tube at high temperature and increased

pressure found sprays of vegetable oil fuels burnt in a different

manner to diesel, where the flame was reasonably uniform.

Vegetable oil fuels produced pockets of burning, some of which

continued for longer than would be available in an engine.

It was thought that these were larger fuel droplets. These

part burnt droplets would cause engine deposits. A second

injection of fuel into high temperature and pressure conditions

was found to rapidly combust in a uniform manner over the

entire reaction volume. [2]

These experiments would suggest that pre injection systems

should help to enable vegetable oil fuels to combust more

completely.

DI engines sometimes utilize two spring nozzle holders to

give a pre injection. The valve is held shut by two springs.

The increasing fuel pressure overcomes the first spring, which

allows a small quantity of fuel to be injected. As the fuel

pressure increases it overcomes the pressure of the second

spring and the main injection event begins.

IDI engines use a number of different pintle nozzles designs

to achieve a pilot injection effect.

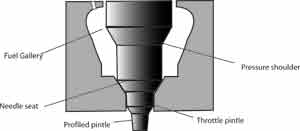

Delay or Throttle Pintle

As the needle lifts from its seat the longer throttle pintle

still largely blocks the injection orifice allowing a small

amount of fuel to be injected. As injection continues the

throttling pintle clears the injection orifice allowing the

main fuel charge to be delivered. Sometimes the throttling

pintle is slightly tapered to provide a gradually increasing

injection rate until the main injection takes place towards

the end of the needle lift. [39,41]

Standard Pintle Nozzle

Throttle/Delay Pintle Nozzle

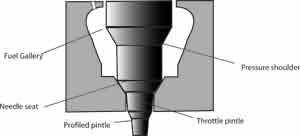

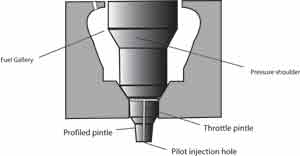

Hole Type Pintle

With this throttle pintle design, as the needle begins to

lift, the fuel is able to flow into small bores that provide

a pilot injection from a spray hole in the centre of the pintle.

Pintaux Pintle Nozzle

The Pintaux nozzles are similar to hole type except the

pilot injection bore is in the nozzle body rather than the

needle. The fuel jet is aimed at the throat from the engine

cylinder to the prechamber. This aids starting as at low needle

lift conditions (such as when the engine is being started)

the main fuel charge is directed at the hot air rushing into

the prechamber where combustion is most likely to occur.

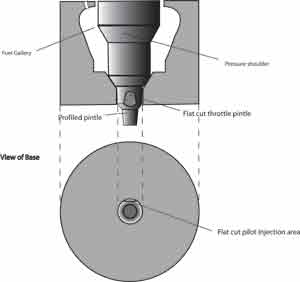

Flat-Cut Pintle

This is a throttling pintle with an additional flat cut

to allow a greater volume of fuel to flow at low levels of

needle lift. As with the hole type pintle the gap between

the throttling pintle and injection orifice is very small

and during the pilot injection phase most fuel flows through

the flat cut area

Industrial and marine engines are available equipped to burn

heavy fuel oils. Injectors fitted to these engines are designed

to provide good atomisation and avoid coking with these thicker

fuels.

Anti-Coking Nozzle Designs

Flat-cut pintle nozzles have been found to be far less prone

to coking due to the increased flow volume within the flat-cut

area that stops deposits forming. [39]

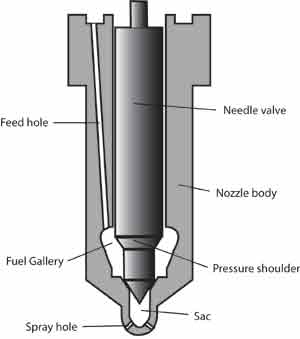

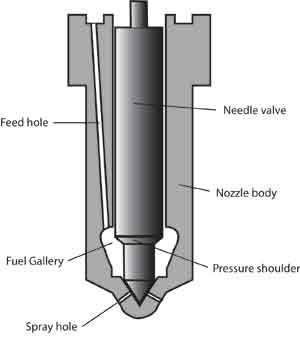

Seat hole or valve covered orifice (VCO) injectors are multi

hole injectors in which the start of the spray hole is located

within the valve seat. With the traditional multi hole injector

design the fuel left downstream of the valve, in the sac and

nozzle holes, is heated by combustion and some fuel enters

the combustion chamber late within the combustion event. This

fuel only partially combusts and causes associated hydrocarbon

emission problems and deposits on and within the nozzles.

VCO injectors help to negate these problems by significantly

reducing the amount of fuel that can leave the injector after

the injection event and by blocking the flow of combustion

products into the injector sac [39,40,41]

Multi hole nozzle

VCO Nozzle

Non VCO injectors are available with a reduced sac capacity

that perform somewhere between standard multi hole and VCO

injectors. Conical sac hole injectors are available which

have a reduced sac volume compared to standard cylindrical

sac injectors. Also injector needles are used with an extension

from the tip to decreases sac volume with the valve closed.

Needle motion sensor, optical ignition sensors, injection

lag, ignition lag and vegetable oil fuels.

NOx emissions have been found to increase with vegetable

oil fuels, it has been suggested that this is due to the larger

molecules found in these fuels which are less compressible

and would lead to a reduced injection lag, that is the time

between fuel being pumped by the IP and being delivered by

the injector nozzle. Advancing the time of combustion is known

to increase combustion pressures and temperatures, which leads

to higher NOx levels. Injectors fitted with needle motion

sensors detect the exact time of fuel delivery and the pump

timing is modified to compensate [39][52].

Toyota introduced an optical ignition sensor that enables

the ignition delay to be observed. The control unit can optimise

the timing to compensate for differing fuels and engine wear

[42].

Glow Plugs

Some vehicles glow plugs have an after glow function where

the glow plugs stay on after starting for a few minutes to

smooth cold running. This function improves poor combustion

within a cold engine.

Upgrade kits are available for some vehicles from both Bosch

and Buru. The replacement plugs are of a heavy-duty construction

to withstand the extended heating times. Buru after-glow plugs

are marked GN for Nachglueh (post-glow) compared to GV for

Vorglueh (pre-glow). Bosch produce Duraterm glow plugs which

are designed for use with afterglow systems. The later Duraterm

Chromium are of a more rugged design.

1 The Diesel Engine

2 Theory of Vegetable Oil Use as a

Fuel

3 Engine suitability

4 Heating the Oil

5 Biodiesel

6 Micro Emulsions and Blends

7 Vegetable Oil Engine Design

8 Vegetable Oil Furnaces and Heaters

9 Oil Types and Filtering

10 Taxation

11 Implications of Vegetable Oil

Fuel Use

12 Sources

|